Maxillum Pool Lighting Innovation and Characteristics

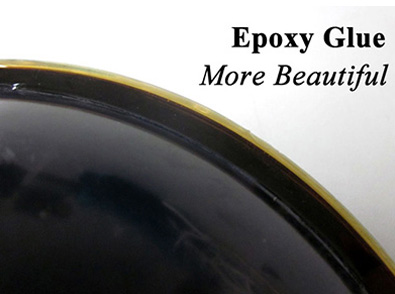

1) Epoxy resin filled technology

With reliable glue filling equipment, the precise percentage as controlled, and the unique design of the lamp panel structure is filled with high-gloss transparent epoxy resin. On the one hand, this process completely solves the problems of water leakage of lamps. On the other hand, it has substantially improved the heat dissipation capability of the lamps, the working heat of LED circuit board has not been accumulated, and they are transmitted into the water as the same working time.

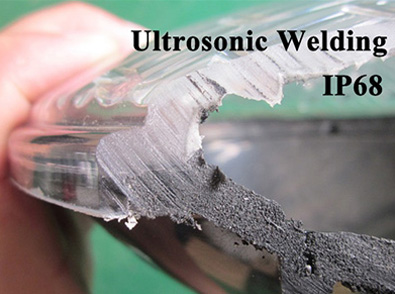

2) Ultrasonic Melting

Ultrasonic machine melt the PAR56 cover and bowl together . two materials mixed together .

Then add the epoxy glue on the edge as the second protection.

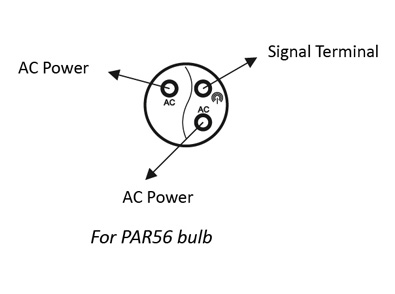

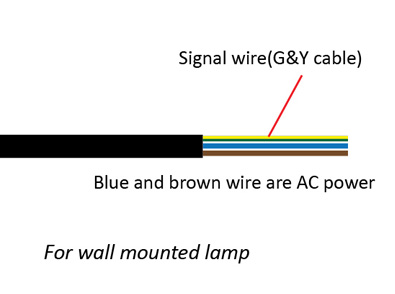

3) Superhet remote control technology

With the three core technology, signal cord extension technology, superhet remote controller technology, and switch box technology, the performance of our lamps working underwater can be controlled by the user simply and freely, and the multi-lamps synchronization is more reliable.